Technical feasibility study can save your MedTech project!

After 50+ MedTech projects delivered at Consonance we can tell one important piece of advice: it’s worth starting your MedTech innovation with technical feasibility study if you want to build the product faster, know risks, a timeline and REAL costs. We explain why this takes some time and money and why this is the best investment before you even start to make big expenses.

Table of Contents

Technical feasibility study: ideation & prototyping

A medical device used by physicians and available at a pharmacy or clinic is a highly developed setup of hardware and software or service that has a unique class of medical device assigned to it in the certification process. It differs from standard devices (gadgets) on the market. When it comes to healthcare, the entire process of prototyping, manufacturing and market implementation is regulated and requires a number of tests and analyses to confirm safety and accuracy. We usually trust doctors and so we trust the devices they use. This is extremely important. On the other hand, patient safety is as important as a doctor is, so the certification process includes both sides.

Before introducing a marketable product, a new medical device needs to be described with a class number and CE certificate for EU or FDA approval which is mostly preceded by clinical experiments or clinical studies. which aims to check correctness of operation. Don’t be surprised if this will take months or years. Would you take these costs and a risk without proof that your idea is technically and clinically possible?

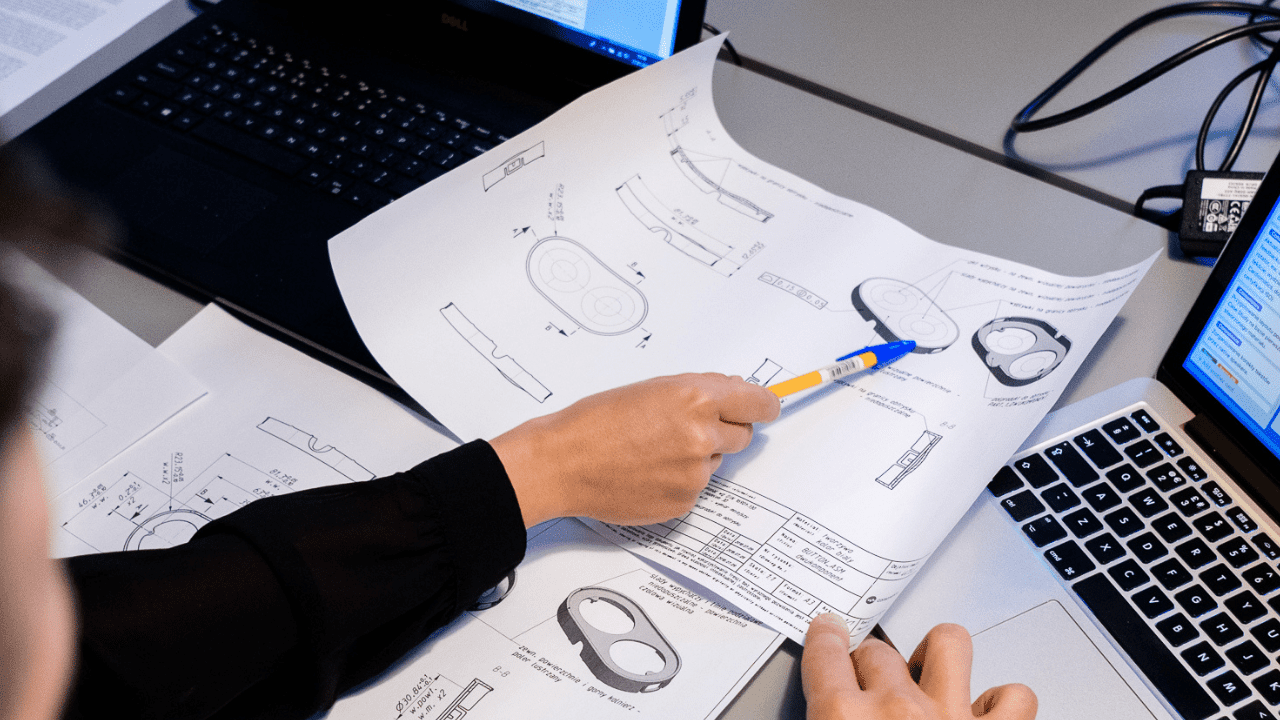

Already at the initial prototyping stage, the whole process should include information on what subassemblies and parts should be used so that the device meets the assumed results and safety requirements indicated by ISO standards.

We reach a stage of fully functional, production-ready prototype and I’m sure this is a big moment. Sometimes it’s the first physical experience with a new healthcare device. It’s usually prepared for the certification process or clinical trials, and after passing them, it enters the production stage.

MedTech product instruction and a roadmap

If someone were to ask me what is the most common mistake made during the development of a medical device, I would answer without hesitation: forgetting about a number of processes, risk analyses and reference products or biocompatibility tests. The result is a rather nervous atmosphere just before certification. While quickly filling out the documentation needed to submit the necessary applications, teams find that their device does not meet the requirements, and months of work and financial resources are irretrievably burned in the project, without bringing tangible success.

A technical feasibility study or a technical audit are documents that by their content represent knowledge, competence and instructions for action in the process of creating a medical device and its certification. They allow us to prepare for the prototyping process, suggest which components to use, what to pay special attention to in terms of design and what challenges we have to face in order for the regulatory office to approve our innovation. In these documents there is also a preliminary analysis of the medical device class, which – after a positive certification process – will be maintained.

If I were to point out a direct benefit – we simply save a lot of hours of work, preparation and, most importantly, we avoid re-prototyping the device due to a change of electronic component or casing design.

Theoretically different from each other, the documents contain similar knowledge. They differ only in the way they approach the content analysis and the level of readiness of the idea, prototype or technology we are studying. A technical feasibility study is a document tailored to an idea or technology that is at the very beginning of technological readiness, where there is an idea of action and preliminary technology, but no prototype, certification path and business background of the whole issue.

In the case of technical audit, this document is created when there is already a prototype or ready device and it needs to be checked in terms of technology and certification and prepare the necessary certification documentation for it.

Measured by figures

I’ve listed a number of advantages and risks that we can prevent by investing in a technology proof of concept for a startup.

But what are the measurable benefits of the “0” stage, if real amounts are at stake?

Let me use an example in which a subcontractor, without prior preparation, values the R&D work at 100 k Euros. He assumes that the creation of electronics, software preparation and selection of components will take 3 months of work and then unofficially the implementation could be left to an outsourced, cheaper workforce. Reality turns out to be different when a project is ongoing.

To implement the project itself, electronics engineers, programmers and project managers spend 3 to 4 weeks, checking the availability of components in the country and e.g. in Asia and create a preliminary idea of operation. Already at the stage of the first month of work, it turns out that the “initial idea” during the valuation did not work. Functions, which were mentioned in the valuation, are in fact much more complicated and need a completely different set of technology than the one planned. After a few weeks, the initial prototyping work begins, and the budget assumed for the production of a prototype has significantly shrunk. There are delays, financial shifts and, as a result, the whole project is in question already at the preliminary stages of engineering work.

My point is: what sets MedTech projects apart is the stack complexity. A medical product is a synergy of initial need, hardware, software, design, and the so-called human factor which appears at the moment of using the device. The latter results in its own way from the previous ones, and it will decide whether a given device will be a market success. Let us remember that medical devices are subject to User Experience assessment. We want to have some form of “pleasure” in using them. Especially if we take into account that most often we use medical devices out of compulsion, not choice.

Loss prevention

Let’s assume that you are planning a project in the area of MedTech. Regardless of who you start it with – ask your potential technology partner about the technical feasibility study or technical audit and what costs you will incur to develop it. For your safety and the safety of your investors – don’t embark on a medical journey without fully understanding the expected outcome with both sides of the project. I would add that the more parties – the greater the likelihood of misunderstanding. It is definitely worth looking for “one-stop” partners who specialize in medical R&D projects.

MedTech Technical Feasibility – what to look for?

Surely you are wondering how much time an experienced team needs to develop a complete and fully usable document? The Consonance project experience shows that it is between 8-10 weeks, provided that the engineers and designers are supported by specialists in certification and business areas.

The result of the work is at least several dozen pages of solid technological analysis and use cases, operating instructions, description of necessary electronic and mechanical components, and the actual finale of the “0” stage is a joint workshop to help in a common understanding of the results.

Feasibility phase in medical device development should help to:

- make major design changes at lower cost than in the development or later phases

- set volume based manufacturing cost estimate

- test the business case for embarking on the program

- refine and iterate of the product concept

- establish a plan for efficient use of product development resources

- estimate program cost and timeline (real estimation)

- align with MDR/IVDR/CE/FDA/ISO requirements for successful product approval or clearance

- establish the foundation for the manufacturing plan development

With the above, you increase the probability of market success. If you happen to receive a quotation and time assumptions for creating a medical product without a technical feasibility study or technical audit – a potential partner unnecessarily increases your business risk and the possibility of not delivering a medical product according to the assumed idea. Even if the product idea would be applicable worldwide or in a niche. Invest only when you have a strong technological and design foundation which proves your idea can be done, is marketable and won’t be out of the financial reach of your target audience.

If you’d like to talk with an experienced consultant about the technical feasibility issues you’re facing, we’re here to help. Just drop a line the author.