Electronics in Medical Devices: Engineering for Precision and Reliability

Electronics in medical devices allows us to check our blood pressure at home, measure our temperature, or rely on hearing aids. In hospitals and clinics, doctors use electrocardiographs, MRIs, defibrillators, and ventilators to keep patients safe and healthy. Pretty important job to do, isn’t it?

These devices are now such a standard part of healthcare that it’s hard to imagine medicine without them. At the heart of every device is electronics – the real “engine” making it all work. Thanks to advances in miniaturization and integration, engineers can now create innovative, portable, and discreet solutions that we can wear and use in everyday life. In this post, we’ll take a closer look at the role of electronics in medical devices.

Why Electronics Matter in MedTech

Electronic medical devices combine medical knowledge with modern technology, serving both diagnostic and therapeutic purposes. Among the most common are devices that monitor patients’ vital signs, such as blood pressure monitors and digital thermometers, as well as therapeutic and rehabilitation devices like insulin pumps and medical inhalers. Advances in technology and miniaturization have also made wearable medical devices possible, some like tattoos, others like exoskeletons that assist with walking and portable insulin pumps.

The development of medical electronics enables continuous 24/7 health monitoring, allowing for remote care, improving the quality of services in hospitals and healthcare facilities, and increasing access to relatively affordable healthcare in regions with limited access to hospitalization. Medical electronics not only support the work of doctors and patients but are also becoming a key tool in telemedicine or home-based healthcare.. But the question is: can you use any electronics available in medical devices?

Regulatory issues pose another major obstacle. Even if the prototype functions as intended, it may turn out that the materials or components used do not comply with the requirements of the MDR (Medical Device Regulation). A lack of knowledge in this area can result in delays, additional costs, or even project failure.

Regulations That Power Safe Medical Electronics

An essential step in developing electrical medical devices is ensuring compliance with the relevant regulations. The most important of these and one you are likely already familiar with, is Regulation (EU) 2017/745 (MDR), the overarching legal framework that defines the requirements for placing medical devices on the European Union market. Alongside regulatory compliance, the design process also relies on harmonized standards. These standards serve as practical tools for meeting MDR requirements and streamline the conformity assessment process.

Key standards include:

- ISO 13485 – Quality management systems for medical devices.

- ISO 14971 – Risk management throughout the medical device life cycle.

- IEC 60601 – Electrical safety and essential performance of medical devices.

- IEC 62304 – Software life cycle processes for medical devices (particularly important if the device includes firmware or software).

- IEC 61010 – Safety requirements for laboratory and test equipment (sometimes used as a supplementary standard).

Medical Electronics Development Journey at Consonance

At Consonance, every medical device project follows a well-defined path from initial idea to a fully functional device ready for clinical trials. When it comes to electronics development, we approach the process in three clear phases:

- Technical Feasibility Study

Every project at Consonance starts with a Technical Feasibility Study, which sets the stage for a safe, effective, and fully compliant medical device. At this early phase, we dive into the functional requirements, explore alternative solutions, and review reference devices, while also assessing the current state of knowledge in the field. These analyses help us uncover potential challenges, risks, and opportunities before development begins.

In the highly regulated medical sector, understanding and interpreting all relevant standards and legal frameworks is essential to ensure compliance from day one. Drawing on these insights, we then craft a concept for the technical solution, including the system architecture, which acts as a blueprint for the entire project, guiding design decisions and ensuring alignment with both regulatory expectations and project objectives.

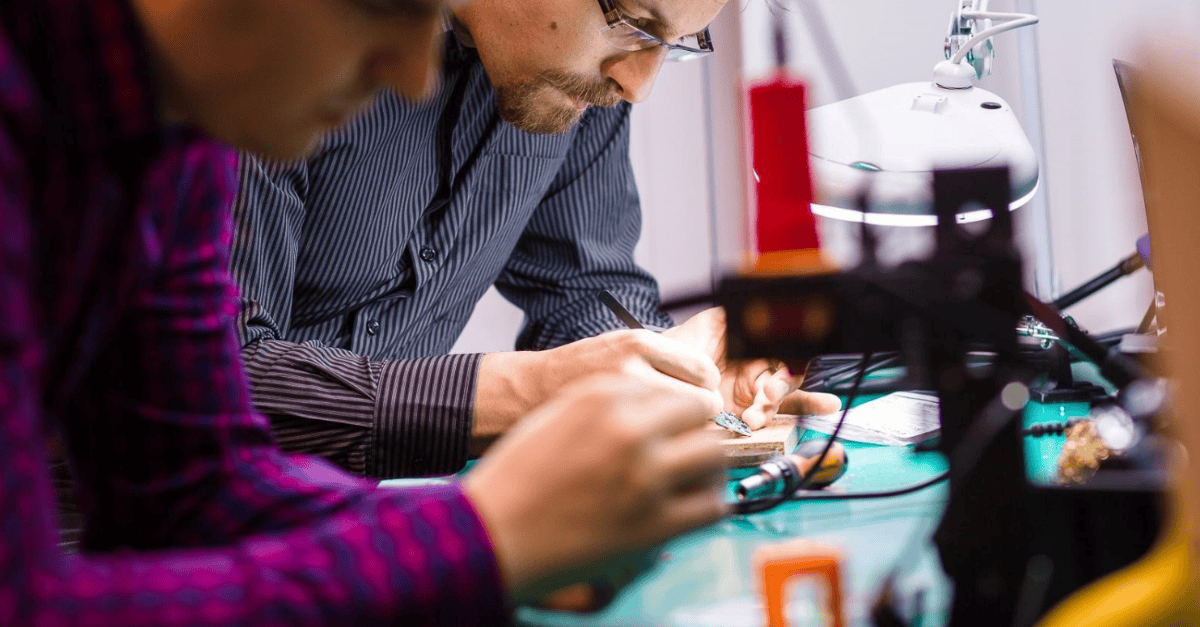

- Building a functional prototype

With the regulatory groundwork in place, we move on to turning the concept into reality. This stage involves sourcing the necessary equipment, refining the technological concept, selecting the right components and suppliers, and testing materials, manufacturing methods, and the device’s construction. The goal? A working prototype that can prove the design’s feasibility through initial functional testing.

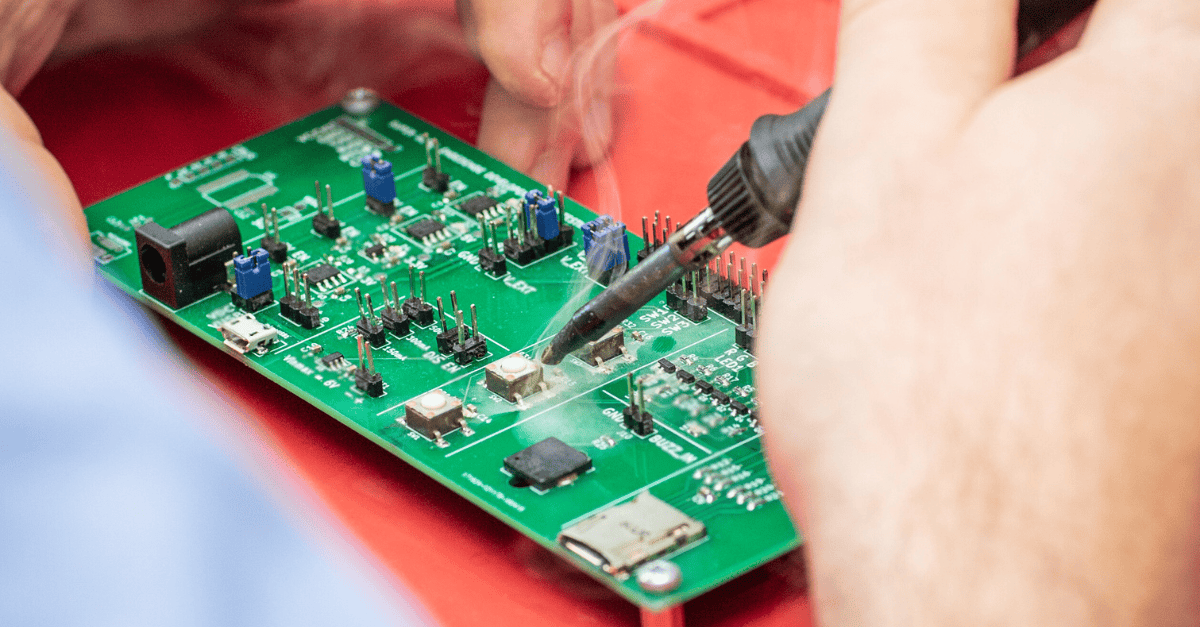

- Creating a device ready for safety and electromagnetic compatibility tests

The next stage, we develop a dedicated solution, complete with electrical schematics, simulations, PCB design, manufacturing, and assembly. We fine-tune measurement systems and carry out preliminary tests to ensure the device is safe, reliable, and ready for use in safety and electromagnetic compatibility tests.

- Clinical evaluation and where applicable clinical investigation

A key step following the development of a clinical – grade prototype is the clinical phase. Clinical investigations are not always required: they may be waived if sufficient clinical evidence is available from literature, registries, or equivalent devices already marketed, or in the case of Class I devices and minor modifications that do not impact safety or performance. Where such data are not adequate, a clinical investigation is conducted in accordance with regulatory requirements to confirm the safety and performance of the device under real world conditions.

- Getting ready for production

In the final phase is preparing the device for production. At this point, if any changes have been made to the enclosure, it is necessary to verify whether they affect the electronics and, if needed, make the required adjustments to ensure compliance with design and regulatory requirements. By following this structured approach, we can confidently guide projects from an initial spark of an idea to a device that meets the highest medical and regulatory standards – ready to make a real impact in healthcare.

Medical Electronics Development Journey at Consonance

Challenges of Electronics in Medical Devices

Designing electronics for medical devices is a unique challenge. On the one hand, there’s constant pressure to innovate. On the other hand, strict regulations and the need for absolute reliability leave very little room for compromise. One of the biggest hurdles is electromagnetic compatibility (EMC). Medical devices must be shielded from external interference and at the same time, they can’t generate disturbances that could affect other equipment in the hospital. Proving that a device meets these standards requires accredited EMC testing, which makes the design process longer and more expensive.

Challenges of Electronics in Medical Devices

Software brings its own set of challenges. Complex code often dictates the hardware requirements, pushing designers toward larger memory, more powerful microcontrollers, or even full processors. Naturally, this increases unit costs. Longevity is another critical factor. Medical devices can’t rely on components that disappear from the market after just a couple of years. Manufacturers need to ensure availability and support for at least five years and ideally ten. This means carefully choosing parts and working closely with suppliers to avoid the nightmare of having a key component suddenly discontinued.

And then there’s the power supply. Safety standards are so strict that many devices require power supplies with dual safety certification. On top of that, regulations often forbid the use of off-the-shelf consumer chargers, forcing companies to design custom charging solutions. These rules are essential for patient safety, but they also add complexity and increase costs.

Summary

Electronics are the heart of any medical device, the most important part of what makes it work. The process of developing electronics for a medical device is crucial, as the goal is to create a product that is efficient, effective, and highly reliable. Designing such a device is no small challenge, which is why consulting an experienced industry specialist can provide invaluable guidance and support.

At Consonance, we have collaborated on over 100 projects, helping to transform the world of modern medicine and medtech. If you feel that your project could benefit from expert advice and hands-on support, our team is ready to help you bring your vision to life safely, efficiently, and with maximum impact.