Custom Medical Device Development vs. Off-the-Shelf

An idea, securing funding, hiring the right team, prototyping, engineering, clinical testing, and ensuring regulatory compliance. Quite overwhelming, isn’t it?

One of the most critical challenges, especially for first-time innovators, is deciding on the right development approach for a medical product. In practice, two concepts dominate this discussion: off-the-shelf solutions and custom medical device development. They both have distinct advantages and limitations, and the choice between them can significantly influence not only the cost and timeline of the project but also its long-term scalability and compliance. Let’s explore them!

Off-the-Shelf Components – Advantages and Limitations

Off-the-shelf components are readily available hardware products that require no special customization. They typically include microcontrollers, communication modules such as Wi-Fi, Bluetooth, or cellular networks, sensors for measuring heart rate, motion, ECG, or SpO2, as well as embedded systems, including evaluation modules and development boards.

Using these components in medical device development offers several advantages. They enable rapid prototyping and faster product launch, shortening the overall development cycle. Production costs are relatively low, and proven solutions ensure efficient mass production, durability, and component interchangeability. Fully integrated system-on-chip modules provide a notable example, minimizing the number of components in the bill of materials and thereby reducing both production time and costs at scale. Additionally, manufacturers often provide support through hardware and software tools, which simplifies system integration and testing.

Nevertheless, there are limitations. Off-the-shelf components may not fully meet specific mission or user requirements, and companies relying on them are dependent on supplier decisions, which introduces the risk of product recalls and potential supply chain disruptions. At a large scale, unit costs can also be higher. Furthermore, using off-the-shelf modules often requires working with manufacturer libraries and SDKs, limiting flexibility when implementing custom features or integrating with proprietary software. In the context of IWMD devices, the limited number of COTS component manufacturers can create market monopolies and significantly increase costs. The need to modify components and address integration issues between modules can further complicate the development process.

Off-the-shelf components advantages and limitations in medical device development

Custom Medical Device Development – Strength and Challenges

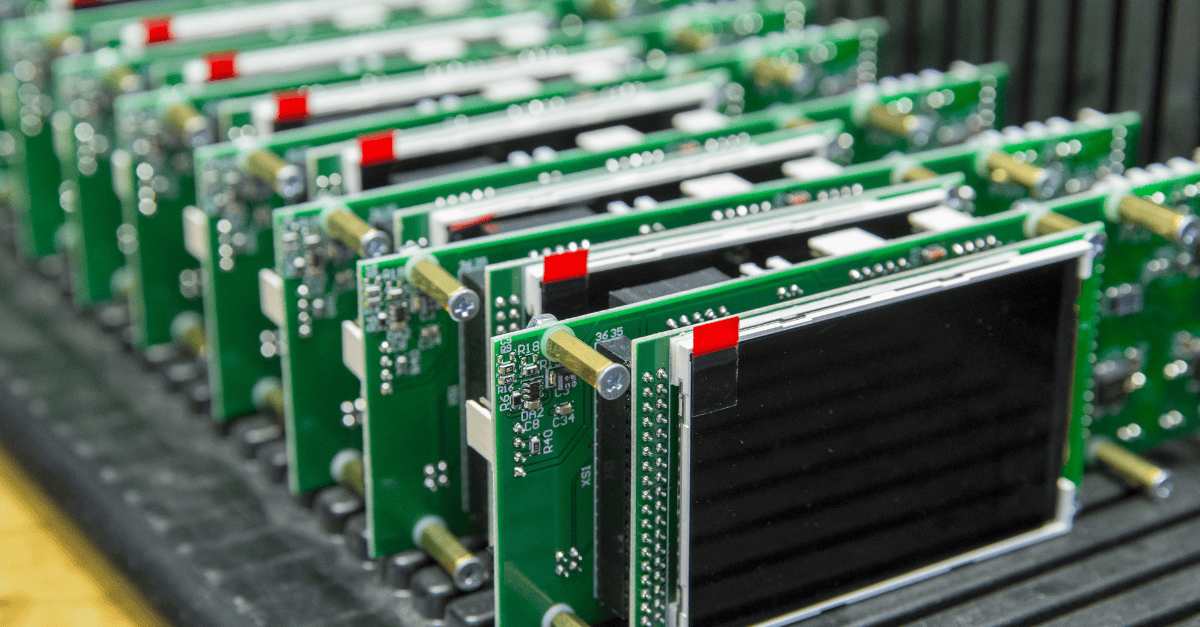

Custom development involves designing and creating physical components and complete electronic devices tailored specifically to medical and product requirements. Each device is engineered from the ground up to meet the unique clinical and operational needs of healthcare facilities, patients, and medical professionals. The development process follows a systems engineering approach, with all elements: PCBs, integrated circuits, microprocessors, sensors, and enclosures, functionally and mechanically optimized for their intended application. Device enclosures are also carefully designed, providing both functional and aesthetic value.

Although custom development provides enhanced design adaptability and functional optimization, it entails higher initial capital expenditure. For instance, creating a bespoke injection-molded enclosure is substantially more costly than employing commercially available off-the-shelf housings. Production timelines are longer, as each component requires detailed design verification, prototyping, and validation. Unit costs can also be significant in low-volume production runs, and navigating regulatory compliance and certification processes (MDR, ISO 13485, IEC 60601) adds additional complexity.

Nevertheless, custom development in MedTech is particularly advantageous because it enables precise alignment with patient-specific requirements and planned specifications. Devices can be optimized for performance, form factor, and energy efficiency, critical for wearable and implantable medical devices. Firmware, circuitry, and hardware are purpose designed to minimize energy consumption and maximize reliability. Moreover, manufacturers retain full control over technical documentation and quality assurance, ensuring regulatory compliance from the outset. As production scales, unit costs decrease, and dependence on external suppliers is minimized, providing long-term economic and operational benefits. Risk assessment and mitigation strategies are integrated at each stage of development, ensuring high-reliability design and patient safety.

How to approach software development in MedTech?

The situation is similar for software: solutions can either be purchased off-the-shelf or developed entirely from scratch. Examples of off-the-shelf software include operating systems such as Windows or Linux, third-party libraries for image processing, or database engines like MySQL. Utilizing these solutions can significantly reduce development time and costs. The FDA has even issued guidance documents to ensure patient safety when integrating commercial software into medical devices.

Proponents of off-the-shelf software argue that custom software development is often prohibitively expensive, and the market already provides numerous solutions that can be adapted for medical applications. On the other hand, fully custom software can be precisely tailored to meet unique requirements. Certain clinical or operational needs may be so specific that no off-the-shelf solution exists. Examples include mobile applications that monitor vital signs, software for analyzing X-ray or MRI images, and AI-based tools that interpret personalized patient data. Custom development ensures that the software aligns perfectly with the device’s intended functionality, optimizes performance, and maintains compliance with regulatory requirements.

Custom medical device development can build unique value for patients.

Choosing Best Solution For a Medical Device

Selecting the optimal approach for a medical device is a critical decision. With over 10 years of experience collaborating with startups, physicians, and entrepreneurs, Consonance has developed a proven methodology for delivering effective and efficient solutions. Each project is approached individually, beginning with a comprehensive technical feasibility study. This study includes requirement specifications, literature and state-of-the-art reviews, reference product analysis, regulatory requirement assessment, technical audits, and an initial concept of the solution.

We present clients with all viable options, outlining the advantages and limitations of each approach, ensuring that the final solution meets both clinical and business expectations. Component selection is guided by the intended purpose of the device: off-the-shelf solutions are leveraged where cost efficiency is possible, while fully custom components are designed from scratch where complete personalization is required. Partnering with Consonance provides peace of mind, as the resulting solution is tailored to address unmet medical needs, optimized for cost-effectiveness and scalability. All components are selected with longevity in mind and comply with applicable regulatory standards and legal requirements, ensuring high reliability and patient safety.

Summary

As we have seen, there is no single “perfect” approach to developing a medical device. On one hand, off-the-shelf components can accelerate production timelines and reduce costs short-term, but they come with limitations in customization and long-term flexibility. On the other hand, custom development offers full control, optimization, and tailored functionality, though it requires greater investment of time, resources, and expertise. What truly matters is that every medical device remains safe for patients, compliant with regulatory standards, and effective in fulfilling its intended clinical purpose. In this regard, there can be no compromises.

Ready to bring your medical device idea to life? Let’s build it together.

Sources:

https://pmc.ncbi.nlm.nih.gov/articles/PMC9144583/

https://www.sciencedirect.com/science/article/pii/S2153353922006186