MedTech product: 6 reasons to partner with Contract Development and Manufacturing Organizations (CDMO)

Should MedTech startups or academic spin-outs partner with Contract Development and Manufacturing Organizations (CDMOs)? It’s tempting to push the project alone and consume the glory, yet these organizations play a pivotal role in driving innovation, streamlining production processes, and ensuring the delivery of high-quality medical devices and technologies. This article explores the multifaceted role of CDMOs in the MedTech product development, examining their contributions to innovation, regulatory compliance, and market competitiveness.

Understanding CDMOs in MedTech

CDMOs are specialized entities that provide end-to-end services to MedTech companies, encompassing product development, manufacturing, and even regulatory compliance. Their role is particularly crucial for smaller or newer MedTech firms that may not have the resources or expertise to handle every aspect of the product development life cycle. By outsourcing certain tasks to CDMOs, companies can focus on their core competencies, accelerate time-to-market, and leverage the specialized knowledge and capabilities of these organizations.

Accelerating Innovation in MedTech

Innovation is the lifeblood of the MedTech industry, and CDMOs play a significant role in driving this innovation forward. These organizations often have dedicated research and development teams with expertise in various technological domains. By collaborating with CDMOs, MedTech companies gain access to a wealth of knowledge and resources, fostering a culture of innovation.

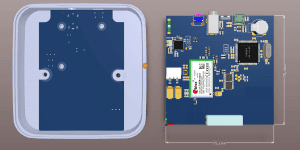

CDMOs are equipped to handle the challenges associated with designing and developing cutting-edge medical devices. From advanced materials to novel manufacturing processes, these organizations are at the forefront of technological advancements. This collaboration enables MedTech companies to bring new and groundbreaking products to market faster than if they were to handle every aspect of development in-house.

The two main goals engineers have when starting new product development are making sure it can be manufactured and reaching development efficiency.

When it comes to development efficiency, internal engineers frequently try their own rapid prototyping at first. Still, the process of aligning it with the certification strategy and standards should start with the research phase.

Navigating Regulatory Challenges

Regulatory compliance is a critical aspect of the MedTech industry due to the stringent regulations imposed by health authorities worldwide. CDMOs specialize in navigating these complex regulatory landscapes, ensuring that products meet the necessary standards and requirements. From initial design validation to final product testing, CDMOs are well-versed in the regulatory processes that govern the MedTech sector.

Collaborating with CDMOs provides MedTech companies with a strategic advantage in terms of regulatory compliance. These organizations keep abreast of the latest regulatory changes, ensuring that products are developed and manufactured in accordance with the latest guidelines. This proactive approach minimizes the risk of regulatory setbacks, such as product recalls or delays in market approval, which can have significant financial and reputational consequences.

Optimizing Manufacturing Processes

Efficient and scalable manufacturing processes are crucial for the success of any MedTech product. CDMOs bring a wealth of experience in optimizing manufacturing processes, leveraging economies of scale to reduce production costs and improve overall efficiency. This is particularly beneficial for smaller MedTech companies that may not have the infrastructure or expertise to achieve such optimization independently.

CDMOs invest in state-of-the-art manufacturing facilities and technologies, ensuring that products are produced with the highest quality standards. Additionally, these organizations often have a global footprint, allowing for strategic distribution and logistics planning. By outsourcing manufacturing to CDMOs, MedTech companies can focus on marketing, sales, and distribution, confident that the production processes are in expert hands.

Mitigating Resource Constraints

One of the primary advantages of partnering with CDMOs is the ability to mitigate resource constraints. Developing and manufacturing medical devices requires a diverse set of skills, ranging from research and development to quality control and regulatory affairs. Smaller MedTech companies may find it challenging to assemble an in-house team with the necessary expertise across these domains.

CDMOs offer a comprehensive solution to resource constraints by providing access to a diverse talent pool. These organizations have experts in various fields, allowing MedTech companies to tap into specialized knowledge without the need for extensive in-house hiring. This flexibility is particularly advantageous in dynamic and rapidly evolving fields, where having the right expertise at the right time can make or break a project.

Enhancing Cost Efficiency and Flexibility

Cost efficiency is a perennial concern in the MedTech industry, where research and development, along with regulatory compliance, can incur substantial expenses. CDMOs, with their economies of scale and specialized expertise, offer a cost-effective solution for MedTech startups. By outsourcing certain functions, companies can reduce fixed costs associated with maintaining in-house capabilities for every stage of the product life cycle.

Furthermore, the flexible nature of CDMO partnerships allows MedTech companies to scale their operations based on demand. This scalability is particularly crucial in an industry where market dynamics can change rapidly. CDMOs provide a buffer against the uncertainties associated with fluctuating demand, enabling companies to adapt to market conditions without compromising on quality or efficiency.

Facilitating Technology Transfer and Knowledge Exchange

Collaborating with CDMOs facilitates technology transfer and knowledge exchange between industry players. As these organizations work with various clients across different projects, they accumulate a wealth of knowledge and experience. This knowledge transfer can be invaluable for MedTech companies seeking to leverage the latest technologies, materials, and manufacturing processes.

CDMOs act as a nexus for innovation and information sharing within the industry. This collaborative approach fosters a dynamic ecosystem where best practices are disseminated, and technological advancements are shared across projects. MedTech companies that partner with CDMOs can benefit not only from the expertise of the CDMO team but also from the collective insights gained through diverse collaborations.

Market Launch and Post-Market Activities

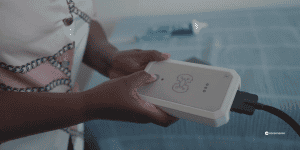

The device is now ready for market launch. Marketing strategies, distribution channels, and training materials are developed to introduce the device to healthcare professionals and end-users. Post-market activities include ongoing monitoring of the device’s performance, addressing user feedback, and making necessary improvements..

Conclusion

In the dynamic and highly regulated landscape of the MedTech industry, the role of CDMOs is indispensable. Organizations like Consonance serve as catalysts for innovation, enablers of regulatory compliance, and drivers of cost-effective and efficient manufacturing processes. By leveraging the expertise and resources offered by CDMOs, MedTech startups can navigate the complexities of product development and bring transformative healthcare solutions to market with speed and precision.

We can help you to move your MedTech product ahead of the curve.