From Concept to Clinic: How Consonance Accelerates MedTech Prototyping?

If you’re here you probably asked yourself is MedTech prototyping such a big deal in the development process? Some medical devices at least externally, aren’t that complicated after all. Or are they?

Before a medical device reaches the market, it must go through a demanding journey filled with technical challenges and critical design decisions. While ensuring the device functions as intended is essential, its form and appearance are just as important, since these aspects are closely tied to the usability. When designing a device, ergonomics and user comfort should always be at the forefront.

Prototyping Unveiled – What It Really Means?

Let’s start with the basics: what exactly is prototyping? Prototyping is the practice of turning an idea into its first tangible form. It’s an iterative process of creating and refining models to confirm user needs and technical requirements. Think of it as the first real-world draft of your concept, something you can test, touch, and improve. In other words, prototyping lays the groundwork for developing and refining the final product. When it comes to medical devices, a prototype serves as the first tangible example of a solution, showcasing its key features, functions, and capabilities before it ever reaches the market.

Balancing these with technical requirements, however, is far from simple. For instance, the need to accommodate electronics and power sources often dictates design choices. If a device is battery powered, for example, the housing must allow enough space for the battery without compromising comfort or functionality. Because initial concepts are rarely flawless, prototyping becomes a vital step. It enables teams to test and refine solutions at relatively low cost before committing to final implementation. In today’s article, we’ll take a closer look at the MedTech prototyping and explain why it is one of the most crucial steps in bringing an innovative medical device to life.

Medical prototyping unveiled. What it really means?

Why is MedTech Prototyping so Important?

First and foremost, prototyping gives you a quick way to visualize the device and evaluate its ergonomics. By sharing the prototype with potential users: doctors, patients, or equipment operators, you can gather invaluable feedback on ease of use, intuitiveness, and practical limitations. A patient might point out that the device feels too heavy for daily use, or a doctor may suggest simplifying the interface. Catching these insights early helps you avoid costly changes later in production.

Testing prototypes reduces the risk of technical flaws and ensures the device meets user expectations. Just as importantly, it accelerates regulatory approval and strengthens confidence that the final product will succeed in real-world use. In short, a well – designed and thoroughly tested prototype is the cornerstone of a successful development process.

Complexity in Medical Device Development

The process of developing a medical device is complex on many levels: regulatory, technological, and interdisciplinary. Prototyping supports each of these areas, helping to structure and guide the entire development cycle. Regulatory complexity arises from the need to comply with the stringent requirements of MDR, FDA, and ISO standards. Through multiple iterations and tests, the risk of ending up with a device that fails to meet these requirements is significantly reduced.

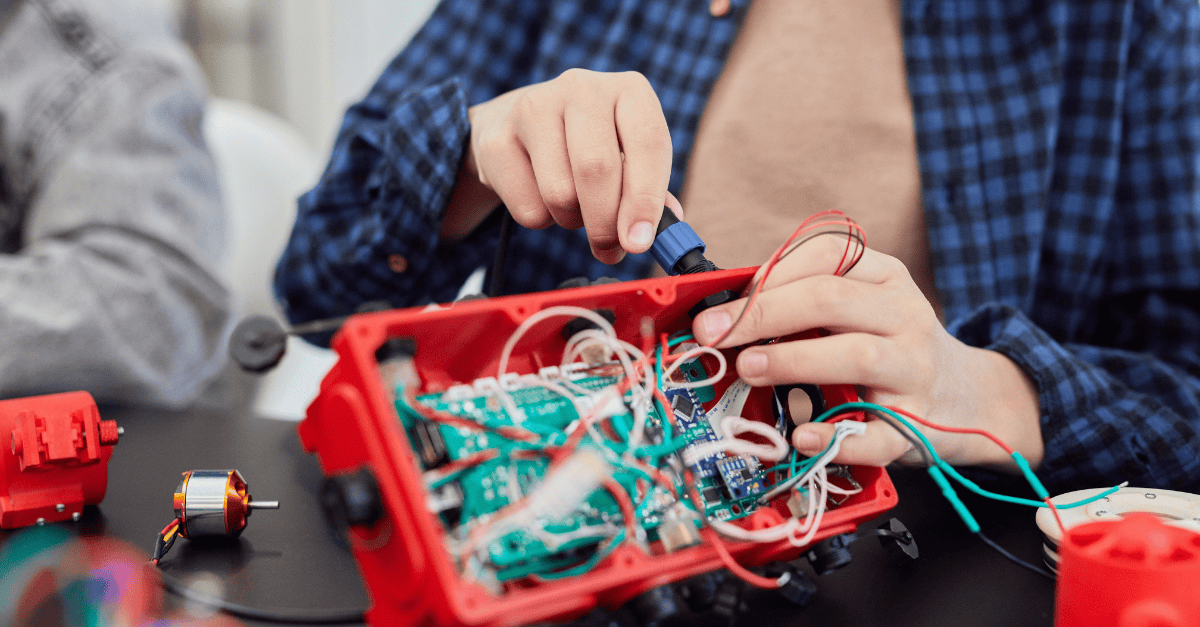

Technological complexity comes from combining electronics, mechanics, software, and user ergonomics into a single solution. In mechanics, challenges include selecting biocompatible materials, designing with a human-centered approach, and ensuring durability while meeting the trend toward miniaturization, particularly in wearable devices. Engineers must create compact, discreet constructions that can still accommodate all the necessary electronics. On the electronics side, circuits must be safe, compliant with medical standards, and resistant to electromagnetic interference with other hospital equipment. Software brings additional hurdles: it must be secure against cyberattacks, integrate seamlessly with healthcare IT systems, and provide accurate, personalized functionalities for both patients and clinicians.

Prototyping makes it possible to verify whether all these elements are properly integrated and work seamlessly together. Interdisciplinary complexity stems from the collaboration of specialists such as engineers, physicians, and regulatory experts. A physical prototype becomes their shared point of reference, facilitating communication and aligning the team’s efforts.

Why is MedTech Prototyping so Important

The MedTech Prototyping Process at Consonance

At Consonance, we support our clients in MedTech prototyping, guiding them step by step from the initial concept to a model ready for clinical trials. We prototype in full compliance with all regulations and certification standards. That means we eliminate the risk of choosing materials or electronic components that won’t meet the requirements of a medical device right from the start.

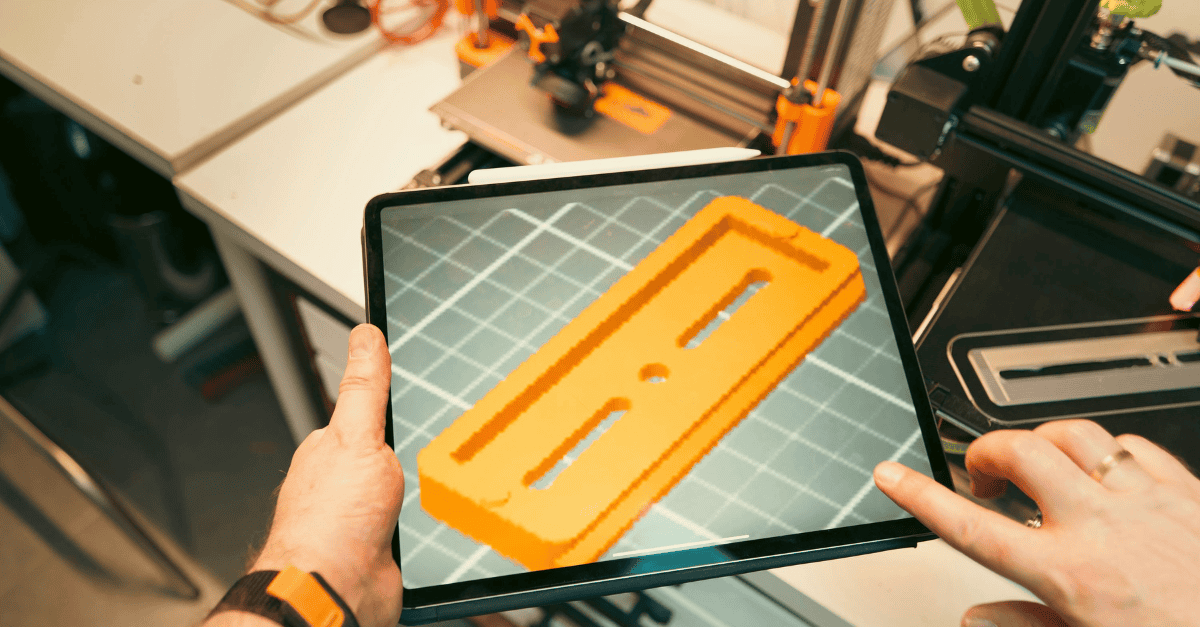

The process begins with alpha prototypes – non-functional models, often created using 3D printing. These early versions make it possible to quickly and cost-effectively check dimensions, ergonomics, and overall shape, helping to minimize expenses at the start of development. The next stage involves beta prototypes – functional models that may not yet match the aesthetics of the final product. Beta versions allow us to test core functions, identify potential design flaws, and collect valuable user feedback.

As development progresses, our team produces further iterations: designing and printing mechanical components, adapting electronics to the intended industrial form, and testing and refining software. This iterative process leads to a prototype ready for clinical trials, with all essential features integrated. Insights from usability tests during clinical trials inform the next refinements: updating the design, creating mechanical and production-ready electronics prototypes, and implementing firmware on the target hardware platform.

The final stage is the production prototype of the device’s mechanics, followed by subsequent versions built with the target manufacturing technologies. Thanks to this iterative approach, we ensure that the finished medical device fully meets both technical standards and user expectations.

Conclusion

MedTech prototyping is the natural next step after creating visualizations and initial designs for your device. Multiple iterations are essential to developing a product that is not only functional but also safe for both patients and users. Investing in prototyping early will always pay off in the later stages of production.

Not sure where to begin? Or perhaps you already have a design but need help turning it into a prototype? At Consonance, our engineers are ready to support you at every stage from alpha prototypes to fully functional models. Get in touch, and let’s shape the future of MedTech together.